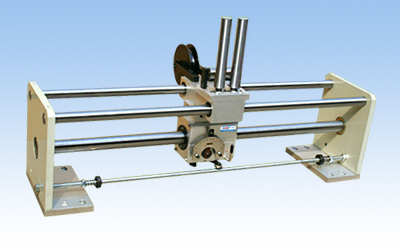

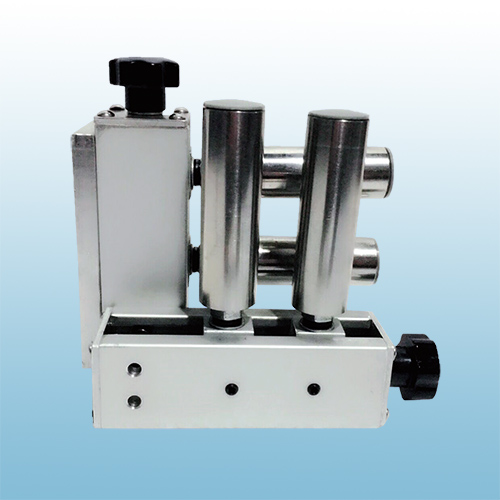

Installation

Mounting the Shaft : To prevent the shaft from being blocked by the dustproof sheath at the both ends of the traverse housing when mounting the...

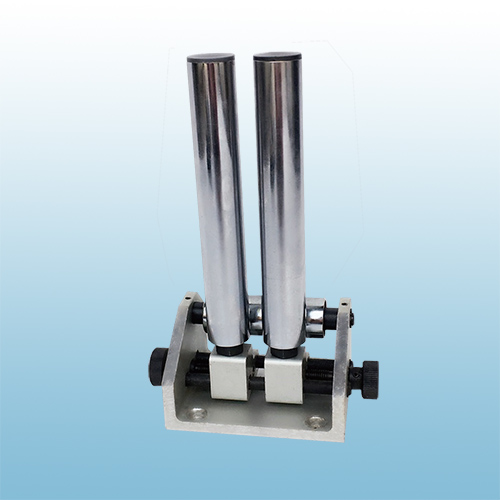

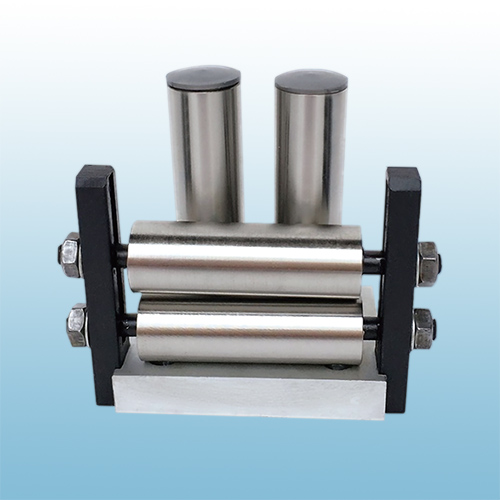

Maintenance

Maintenance : Pay attention to the dustproof work in the working environment. The #20 machinery oil should be applied to the shaft to keep a certain...

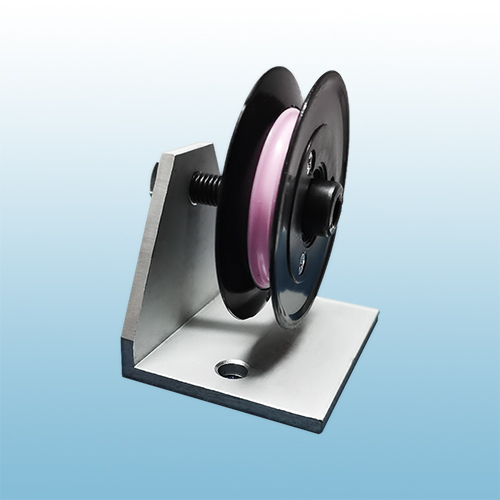

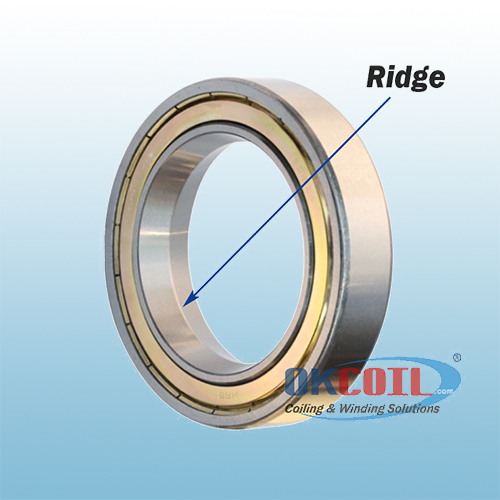

How It Works

Rolling Ring Linear Motion Converts Rotary Motion Input into Linear Output and Enables a Variable Speed, Bidirectional Linear Motion System Without...

©

2008 - 2024

Okcoil Machinery Co. All Rights Reserved